The Sundyne API 610, OH6, Integrally geared pump is safe, reliable, and economical.

Sundyne API 610, 11th Edition OH6 Integrally Gear Driven Pumps are designed for critical high-head, low-flow services required by engineers in the hydrocarbon, chemical, petrochemical, power generation, gas production, and specialty processing industries. They are known for their high suction pressure and wide operating temperature range.

Unlike traditional multi-stage pumps, Sundyne’s computer-tailored hydraulics ensure optimum efficiency by placing the best efficiency point (B.E.P.) at the rated point. This also reduces end-of-curve horsepower requirements and allows for smaller driver sizes to save energy.

Key Specifications:

- Flows up to 400 gpm (73 m³/hr)

- Heads up to 6,300 ft (1,348 m)

- Suction Pressure: 1,000 psi (71 kg/cm²)

- Temperature Range: -200 to 650°F (-130 to 340°C)

The integrally geared line of Sundyne pumps has a vertical configuration that saves space in refineries,

NGL production facilities,

petrochemical plants,

and chemical plants.

Applications include:

- Feed pumps

- Booster pumps

- Bottoms pumps

- Wash water pumps

- Reflux pumps

- Condensate pumps

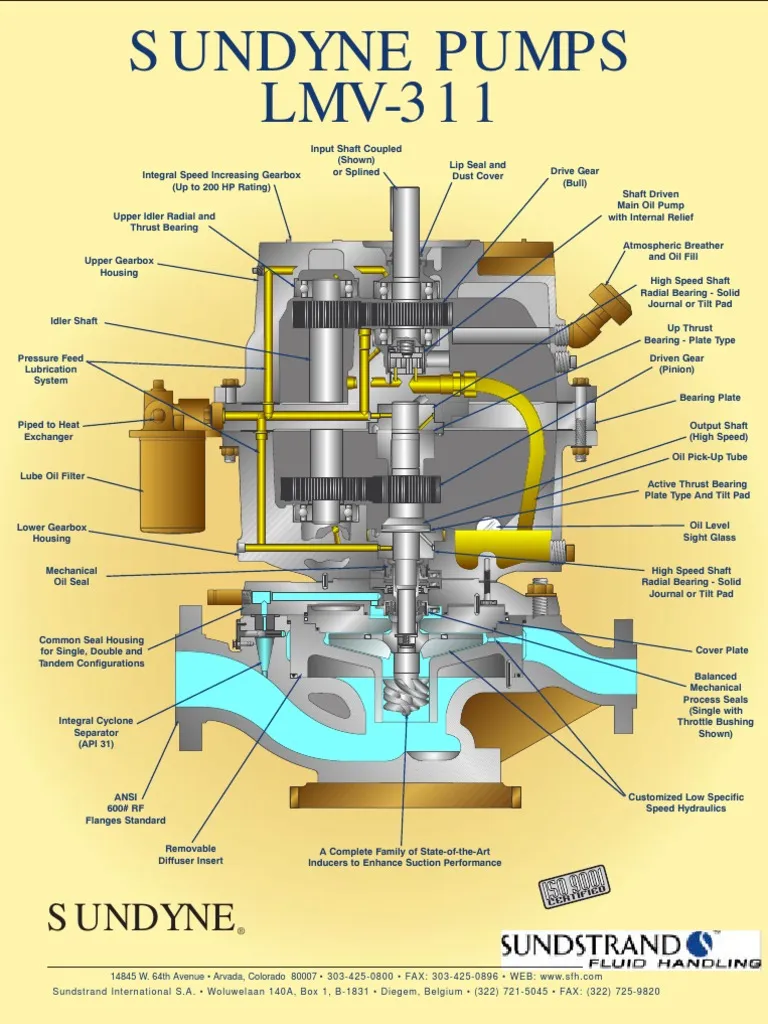

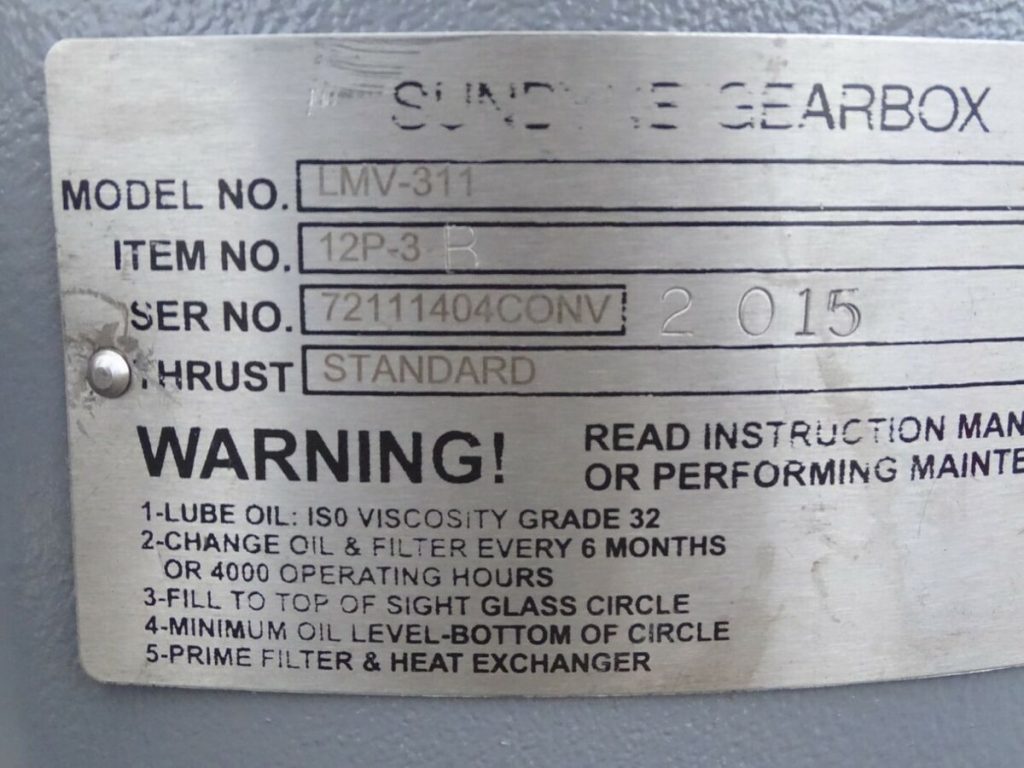

The Sundyne LMV 311 OH6 integrally geared pumps are proven to be reliable, safe, compact, and efficient. They offer several operational benefits:

- They are single stage, vertical in-line overhung pumps that adhere to ISO 13709/API 610 OH6 design recommendations for integrally geared pumps.

- They maximize uptime.

- They save space as they are only 25% the size of competing horizontal pumps.

- They are ATEX certified.

- These pumps can operate continuously for 5 years without requiring an overhaul.

- They utilize Barske impeller low NPSH technology.

- The pump engineering is optimized to meet the BEP (Best Efficiency Point), resulting in energy savings through improved efficiency.